The sDRY MM / MD dryer series offers a fully modular drying management system. The system consists of one sDRY MM main module and can be flexibly combined with up to twelve sDRY MD drying modules. Each drying module can be operated independently and can be expanded or reduced at any time by adding further sDRY MD modules. The system can therefore be adapted to current production requirements by freely combining and arranging the drying modules. It offers maximum flexibility without interrupting the production process.

The series consists of one sDRY MM main module. This can be supplemented with up to twelve sDRY MD drying modules. Drying capacities from 900 to 5400 m³/h can be achieved. This drying can be combined with a wide range of sDRYBIN A drying bins from 15 to 2400 litres.

The sDRYBIN A drying bins are equipped with an intelligent and independent control system. The series consists of drying bins with a volume from 15 to 2400 litres. This series can be flexibly combined with the sDRY MM / MD drying system, which can be flexibly extended or reduced at any time with additional drying bins.

The sCOMPACT dryers are designed with flexibility in mind. The compact dryers offer an integrated solution, combining the drying and conveying of the raw material in one unit. The dryers are available in three versions and are each equipped with one drying bin of the size 80, 150 or 250 litres and up to 2 hopper loaders with a capacity of 4 litres each. As standard, this compact dryer is equipped with dew point control, overdry protection and dry air conveying function with line purging.

Thanks to a modern 7″ touch screen colour display, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected.

The new sDRY 250 dry air generator offers the ideal price-performance ratio for standard applications in the drying of granulate. The sDRY 250 has a dry air capacity of 250 m³/h. The dry air generator can either be operated with a single drying bin or combined with multiple preconfigured drying bins in your plant. The drying bins are available from 100 l to 900 l sizes. This gives you the maximum possible flexibility and an uninterrupted production flow. For more energy efficient drying, additional functions such as dew point control or return air cooling can be added.

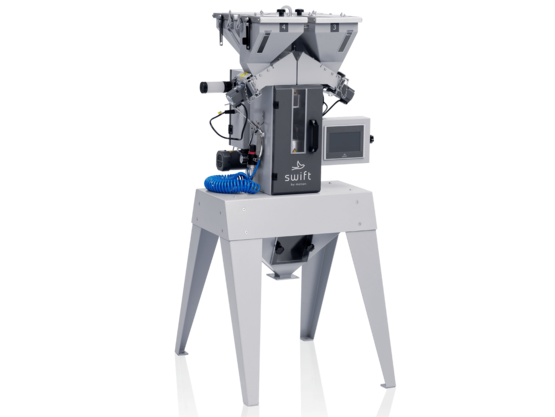

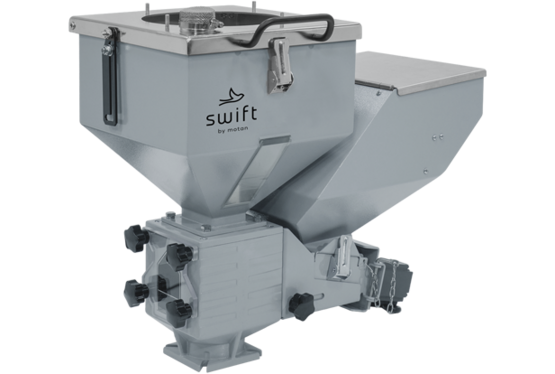

sBLEND G gain-in-weight dosing and mixing units accurately dose and mix up to four materials. These modular, gravimetric units are available in sizes 50, 130 and 300 with the largest unit having a total average throughput of up to 300 kg/h. The units operate with two different types of dosing: vertical slide valves for the main components and up to two screw feeders for high accuracy dosing of additives.

The sBLEND G is equipped with an advanced microprocessor control system. It can display and monitor throughput and provides calibration support. The sBLEND G can be operated locally or remotely via Ethernet.

Combining additives with the virgin material at the processing machine requires excellent mixing quality and consistently accurate dosing. These requirements can be achieved and exceeded with the volumetric sCOLOR V dosing and mixing unit. The units are mounted at the feed throat of the plastics processing machine and are space-saving.

Cost-effective and efficient material conveying can be realized with sCONVEY HOS material loaders. This improves the overall process management of your system.

The plastic granules are transported quickly and cleanly into hoppers, drying bin or other dosing and mixing units and fed to the machine as required. This eliminates material wastage and keeps the work-space clean and safe.

With the sCONVAC flexible conveying station, small conveying systems can be operated cost-effectively. The three-phase conveying station can be used for a wide range of central conveying applications with a large choice of blower sizes. The three-phase blower is low-noise and maintenance-free. The station is available with a blower protection filter or optionally a cyclone dust filter with collection bin. The integrated sCONVAC control is equipped with a 7“colour display which can operate up to 12 sCONVEY HOS material loaders and up to 8 purging valves.

motan is a world leading supplier of complex centralised material feed systems. Each system is designed to suit the customer by taking into account individual factors such as throughput, materials types, and plant layout. A wide selection of loaders with a variety of conveying options, controls, blowers, and filter techniques allow the creation of the optimum system for the customer’s facility.