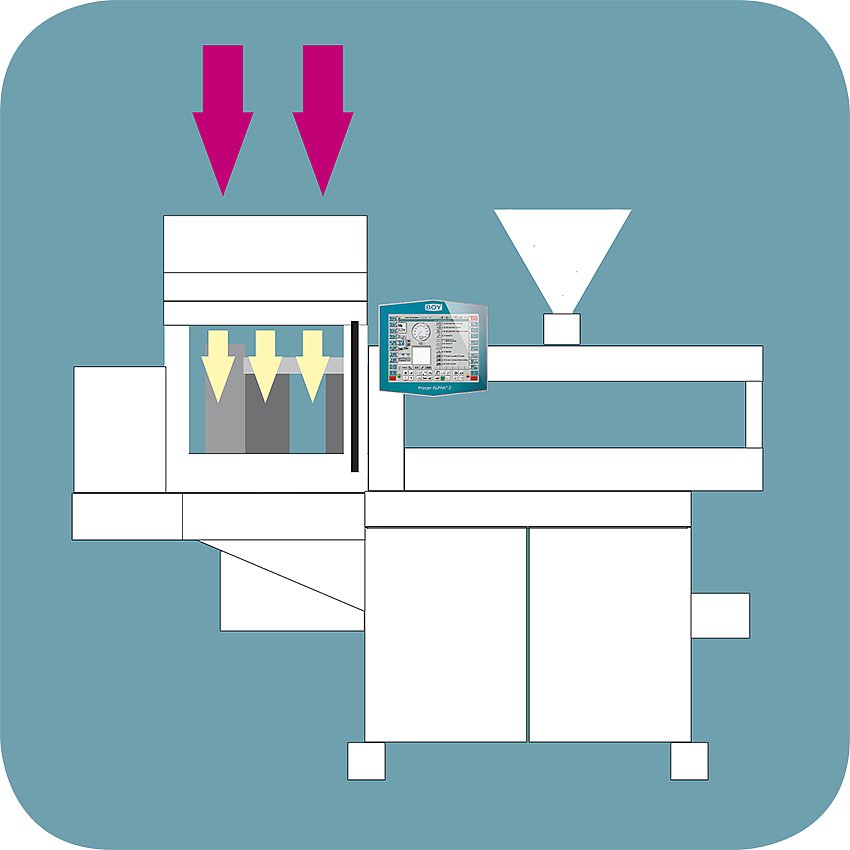

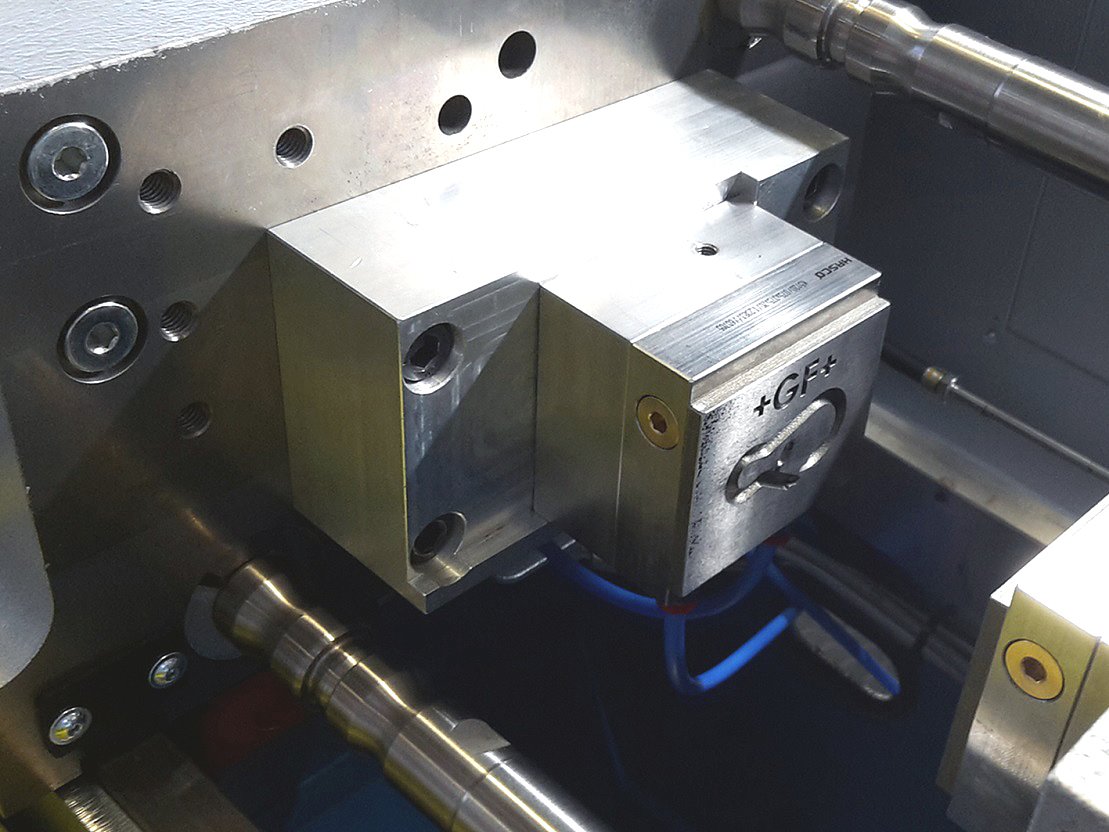

The design concept of BOY injection moulding machines with cantilevered two-platen clamping unit is ideally suited for the production of medical parts and cosmetics under clean room conditions.

The operating elements, hydraulics, water cooled drive motor, and material feed system can be left outside the clean room.

Due to the use of modular system components, different clean room classes can be accommodated.

An overview of the available clean room concepts, you can find in our special brochure “Economic Clean Room – Technology”.

On request we will send you a pdf. file or a brochure.

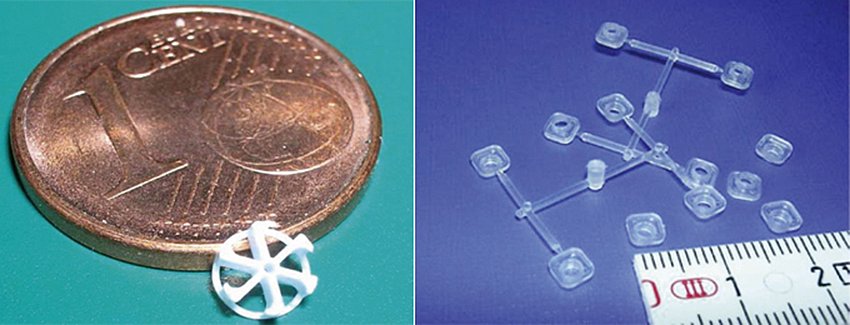

BOY injection moulding machines: Optimal for medical technology

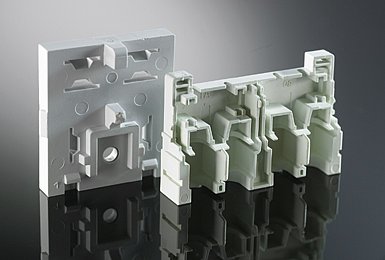

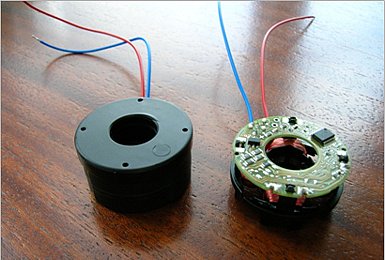

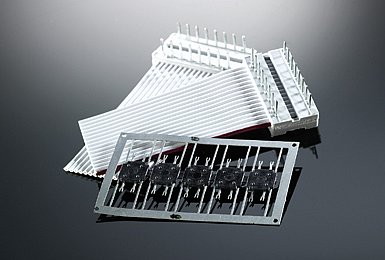

Through the modular assembling of BOY injection moulding machines, applications in clean-room conditions can be realized. Also here, BOY injection moulding machines illustrate their advantages by the capability to process many different materials. Besides the processing of thermoplastics, BOY designed special machine configurations for different applications and special materials through continuous research and the support of customers and well-known specialists. These special designs and technical BOY injection moulding machines: Optimal for medical technology

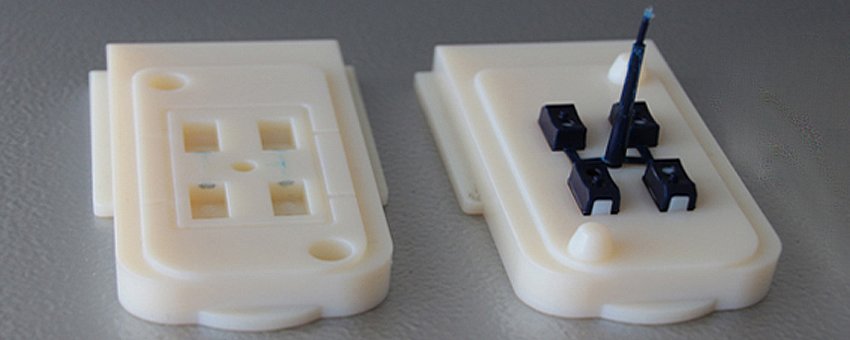

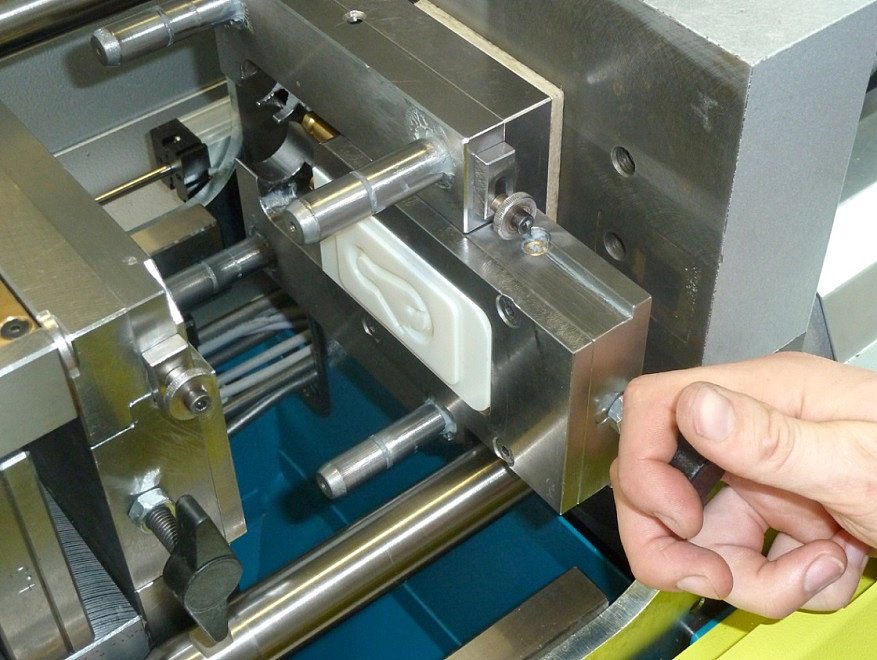

The following applications and special solutions are possible on BOY injection moulding machines: Thermoplastic, elastomer, silicone, PIM, hotmelt, insert moulding, micro injection moulding, and clean room techniques.